On September 15, 2022, the 2022 Iron and Steel Industry Carbon Reduction and Collaborative Management Carbon Neutral Forum, jointly organized by Lvse Jiangnan Center for Public Environmental Concern, Public Environmental Research Center (IPE), Alaska SEE Pearl River Project Center, Changle Metallurgical Association, and Danyang Longjiang Iron and Steel Company Limited was successfully held in Suzhou. The event was attended by important guests from ecological and environmental departments at all levels, industrial park management committees, experts, enterprise representatives, foundation representatives, etc.

Mr. Mao Tao, Director of the International Cooperation Department of the International Economic and Technical Cooperation Center of the Ministry of Industry and Information Technology and Deputy Secretary General of the China Green Supply Chain Alliance, shared the relevant laws, policies, and practical research of the steel industry in the context of carbon neutrality. With the successive release of China's carbon-neutral "1+N" series of policies, the carbon reduction path of the iron and steel industry has become clearer and clearer, which focuses on the need to attach great importance to the issue of steel scrap resources and steel scrap recycling. Finally, we put forward suggestions to ensure the healthy development of the steel scrap industry in four aspects.

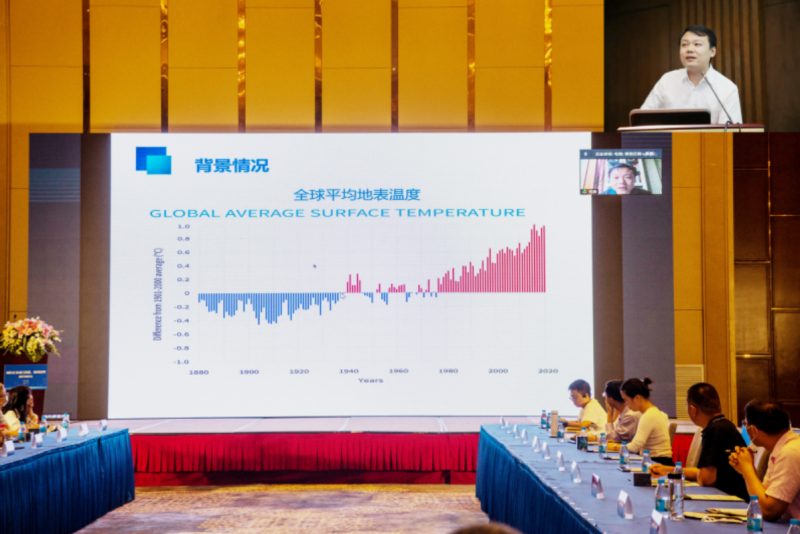

Dr. Yang Pingjian, Director of Environmental Sociology Research Office of China Academy of Environmental Sciences, shared the theme of "Dual Carbon Strategy to Promote High-Quality Economic and Social Development". He mentioned that climate change is a common global challenge, and China has set the goal of achieving a carbon peak by 2030 and carbon neutrality by 2060 from the perspective of building a global community of destiny. Dr. Yang pointed out that achieving the double carbon target on time is a big test, a hard battle, and a systemic project. China has an important position in the process of helping the world to achieve carbon neutrality, and the challenges are enormous. Whether from international responsibility or from domestic demand, China must unswervingly promote the dual carbon strategy to force high-quality economic and social development. In response to the problems and challenges in the process of promoting "double carbon", Dr. Yang put forward a series of recommendations on behalf of the group.

Reducing pollution and carbon is the bottom line for the survival and development of enterprises. Mr. Wu Xian Yang, Vice General Manager of Zhongtian Iron and Steel Group Co., Ltd., from the practice of iron and steel enterprises to reduce pollution and carbon, firmly "energy transformation, green development"; through environmental protection to promote enterprise innovation and green development, become the engine to promote enterprise quality development, green development, environmental protection development as the bottom line of the enterprise.

Be a green practitioner of the harmonious coexistence of plants and nature. Mr. Lv Jiyong, Deputy General Manager of Longteng Special Steel Co., Ltd. focused on the efforts made by Longteng Special Steel in practicing green and low-carbon. Safety is the red line of life, and environmental protection is the bottom line of life; we are striving to build a model of harmonious coexistence between factories and nature.

To further understand the current situation of pollution reduction and carbon reduction in China's steel industry, guests watched the video "Where is the way out for steel enterprises to reduce emissions" jointly produced by four environmental protection organizations, namely Lvse Jiangnan, IPE, Creative Environmental Protection, and Green Walk Qilu. The video includes more than forty steel enterprises researched by the four NGO partners over the past year.

Fang Yingjun, the founder and director of Green Jiangnan (PECC), mentioned that Green Jiangnan has spent more than a year researching 41 steel enterprises and submitted 19 environmental research reports to 17 local ecological and environmental departments, promoting more than 15 billion yuan in funding for the implementation of environmental management. Although some steel companies have deficiencies in environmental management, most of them are performing well. Green Jiangnan, as an environmental organization, plays an important role in social and environmental governance. Director Fang stressed: "We eliminate pollution, not to eliminate polluting enterprises, but to promote polluting enterprises to cure pollution and thus eliminate pollution".

Mr. Liu Ke, Director of Hunan Creative Environmental Protection, shared the story of NGO partners' actions to reduce pollution and carbon in the steel industry. From ordinary people to volunteers to activists to advocates, leaders, and supporters, Director Liu Ke insisted on recording images of those people and stories who act on the front line of environmental protection.

Mr. Ma Jun, founder, and director of the Public Environment Research Center (IPE), released the Corporate Pollution and Carbon Reduction Index and the report of the Pollution and Carbon Reduction Index evaluation conducted by IPE and Lvse Jiangnan on 30 A-share listed steel companies.

Mr. Ma Jun pointed out that in the process of blue sky defense and pollution battle, the overall environmental performance of a number of listed steel enterprises has improved significantly, but as a high-emission industry, there is still much room for improvement in terms of ultra-low emission transformation and whole-process pollution prevention. The leading enterprises, represented by Baosteel, have set GHG emission reduction and carbon neutral targets for themselves and their value chains, and are exploring multiple emission reduction paths. But most of them are at the beginning and need to set GHG emission reduction targets and track the progress of emission reduction on the basis of accounting for GHG emissions. At the same time, they need to explore increasing the proportion of short-process steelmaking, energy efficiency improvement, and raw (fuel) material substitution in accordance with the requirements of the Ministry of Ecology and Environment and other ministries. At the same time, in accordance with the requirements of the Ministry of Ecology and Environment and other ministries and commissions, we need to explore increasing the proportion of short-process steelmaking, energy efficiency improvement, and raw (fuel) material substitution to reduce pollution and carbon.

IPE and Lvse Jiangnan hope that the study of listed steel companies' pollution and carbon reduction index will help companies identify their shortcomings and share best practices, thus helping multiple parties to form a consensus on the roadmap for green transformation and low-carbon development in the steel industry, motivating steel companies to improve their governance and management mechanisms, to clarify their home base through accounting, and then scientifically set greenhouse gas and pollutant reduction targets, efficiently carry out energy saving and emission reduction, and through the disclosure of environmental Through the disclosure of environmental compliance, carbon and pollutant emissions and emission reduction performance, the company will build trust with stakeholders, promote synergy of pollution and carbon reduction, effectively integrate development, conservation and climate objectives, and contribute to the battle for blue sky, double carbon action and global climate governance.

The 14th Five-Year Plan is the key period to achieve the peak of China's carbon emissions, and the hard period to promote high-quality economic development and sustainable improvement of ecological and environmental quality; the road of pollution reduction and carbon reduction and green transformation of China's steel industry is inseparable from the supervision and financial support of government departments, the supervision of the public, and the environmental social responsibility of enterprises themselves.